Emirates takes flight with sustainable aviation fuel at London Heathrow

Emirates, one of the world’s leading airlines, has embarked on a significant step towards sustainability by embracing Sustainable Aviation Fuel (SAF) to power some of its flights departing from London Heathrow Airport. This marks the first time Emirates will be utilising SAF at Heathrow, underscoring its commitment to reducing carbon emissions and contributing to a more sustainable aviation industry.

Under the collaboration with Shell Aviation, Emirates has taken delivery of over 3,000 metric tonnes of SAF blended with conventional jet fuel at Heathrow. This substantial volume of SAF, to be supplied until the end of summer 2024, represents the largest purchase of SAF by the airline to date. Emirates’ participation in Heathrow’s SAF Incentive Programme ensures the affordability and accessibility of SAF for airlines operating at the airport.

Adel Al Redha, Deputy President and Chief Operations Officer of Emirates Airline, expressed the airline’s enthusiasm for this significant milestone, stating,

Emirates is eager to take this next step in our SAF journey with Shell Aviation and London Heathrow supporting us with this fuel supply arrangement in one of our biggest operations outside of Dubai.

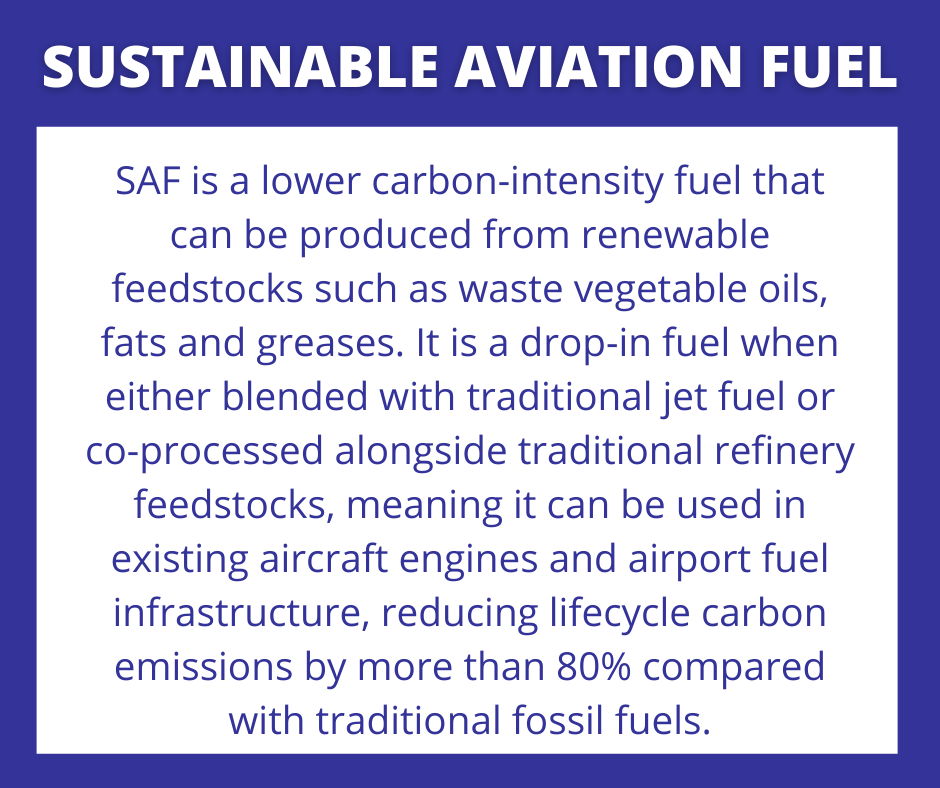

The SAF supplied by Shell Aviation will be integrated into existing airport fuelling infrastructure and aircraft jet engines, adhering to robust reporting methodologies to track and trace its delivery and sustainability attributes. Notably, SAF, in its neat form, has the potential to reduce lifecycle carbon emissions by up to 80% compared to conventional jet fuel.

Raman Ojha, President of Shell Aviation, highlighted the significance of this collaboration, stating,

After our successful collaboration with Emirates to supply SAF to Dubai (DXB) last year, we are pleased to continue our support for their sustainability journey by enabling the airline to decarbonise flights out of the UK.

London Heathrow’s SAF Incentive Programme, launched in 2022, aims to reduce the premium price gap between conventional jet fuel and SAF by approximately 50%, thus accelerating the adoption of sustainable aviation fuels. Ross Baker, Chief Commercial Officer of Heathrow, emphasised the importance of SAF in decarbonising long-haul flights and expressed optimism about supporting the use of up to 155,000 tonnes of SAF at Heathrow this year.

Emirates’ SAF strategy extends beyond Heathrow, with the airline exploring opportunities to utilise SAF wherever available in its network and collaborating on longer-term SAF projects. The airline has already operated flights with SAF from Amsterdam, Paris, Lyon, and Oslo, and plans further collaborations at airports such as Singapore Changi.

Emirates’ commitment to sustainability also extends to its involvement in initiatives like the Solent Cluster in the UK, which focuses on low-carbon investments and aims to establish a Sustainable Aviation Fuel plant capable of producing up to 200,000 tonnes per year by 2032.

For UK-based business travellers interested in exploring sustainable travel options or learning more about Emirates’ flights, contact your Global Travel Management Account Manager.

Notes for Editors:Incorporate direct quotes from Adel Al Redha, Raman Ojha, and Ross Baker.